DIN 975 Threaded Rods Grade 8.8 & 10.9 Specification Guide

DIN 975 fully threaded rods are a core fastener for structural, mechanical, and industrial projects where adjustability, clamping force, and reliable tensioning matter. At Husaini Brothers, we supply DIN 975 threaded rods in Grade 8.8 and Grade 10.9 to customers across the GCC, and beyond.

This guide explains what DIN 975 is, how Grade 8.8 and Grade 10.9 differ, and when engineers, fabricators, and project buyers should choose each strength class.

What Is DIN 975?

DIN 975 is a German standard that specifies the dimensions and tolerances for fully threaded rods (also called threaded bars, all-thread, or studs). These rods:

- Are threaded along their entire length

- Use ISO metric thread profiles (coarse threads per ISO 261 / ISO 965)

- Are commonly supplied in 1,000 mm (1 meter) and 2,000 mm (2 meters) lengths

- Can be cut to custom lengths for non-standard applications

DIN 975 has largely been superseded in scope by DIN 976-1, but it remains widely used in specifications, catalogs, and procurement documents worldwide.

DIN 975 Grade 8.8 Overview

Grade 8.8 refers to the mechanical strength class of the threaded rod, according to ISO property classes.

- Material: Medium carbon steel, quenched and tempered

- Tensile strength: 800 MPa (approx.)

- Yield strength: 640 MPa (approx.)

- Equivalent to ISO Property Class 8.8 under ISO 898-1

Grade 8.8 gives a strong, reliable threaded rod suitable for most structural and mechanical applications where high but not extreme strength is required.

Purpose of DIN 975 Grade 8.8 Threaded Rods

DIN 975 Grade 8.8 threaded rods are designed to:

- Provide a strong and versatile threaded fastener for structural, mechanical, and industrial assemblies

- Join components using nuts and washers where precise adjustability, clamping, or tensioning is needed

- Be cut to custom lengths where standard bolts are too short or impractical

Choose the Best Manufacturer for Threaded Rods

Benefits of Grade 8.8 Threaded Rods

| Benefit | Details |

|---|---|

| High Strength | Grade 8.8 offers excellent tensile and yield strength for demanding but standard structural and mechanical applications. |

| Fully Threaded | Full-length thread engagement with nuts allows easy adjustment and cutting to shorter custom lengths. |

| Versatility | Suitable for structural, mechanical, electrical, HVAC, and general industrial assemblies. |

| Easy to Customise | Can be cut, chamfered, and finished as required for special connections or site conditions. |

| Widely Available | Common in construction and industry, with standard diameters and coatings easily sourced. |

| Thread Compatibility | ISO metric threads compatible with DIN / ISO nuts, washers, and structural hardware. |

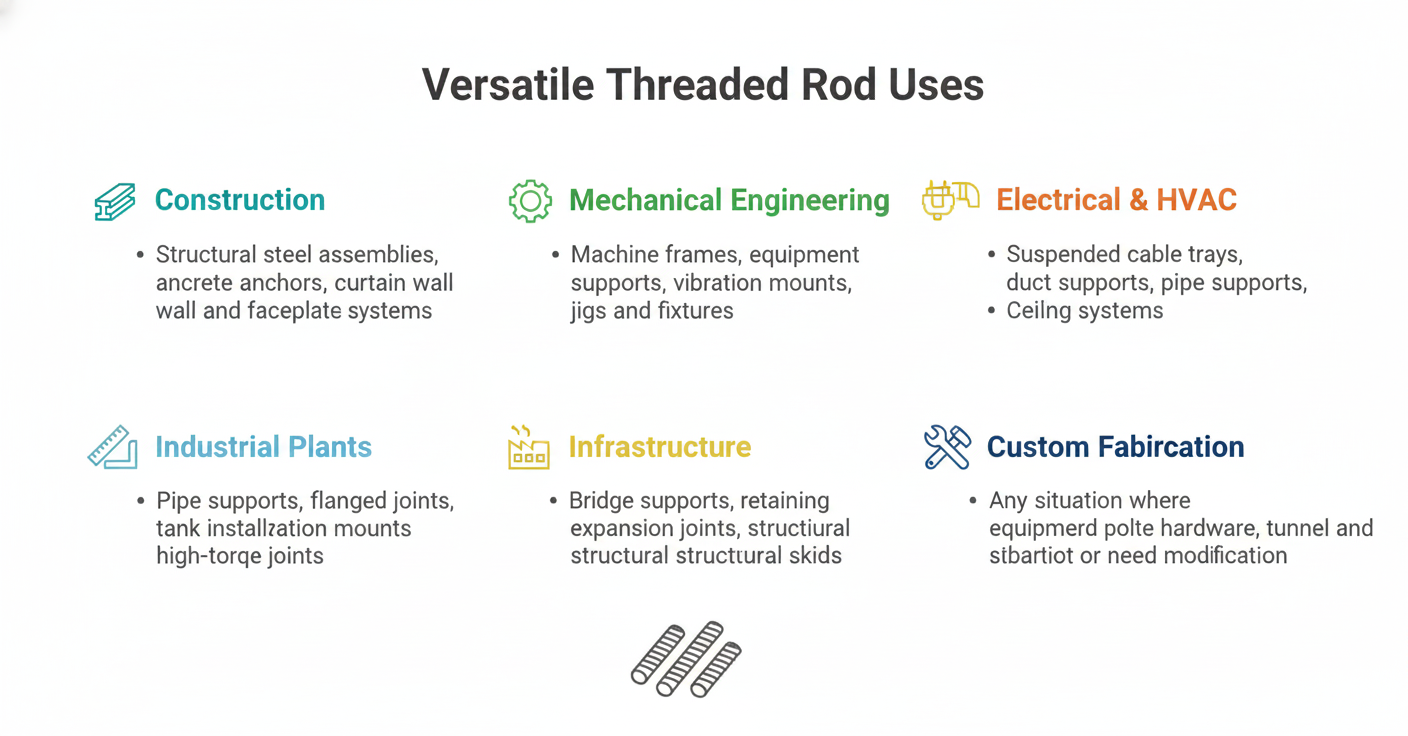

Applications DIN 975 Grade 8.8

DIN 975 Grade 8.8 threaded rods are used across sectors where moderate to high-strength fastening is required.

| Sector | Typical Applications |

|---|---|

| Construction | Structural steel assemblies, concrete anchors, curtain wall and facade systems. |

| Mechanical Engineering | Machine frames, equipment supports, vibration mounts, jigs and fixtures. |

| Electrical & HVAC | Suspended cable trays, duct supports, pipe hangers, ceiling systems. |

| Industrial Plants | Pipe supports, flanged joints, tank installations, process equipment mounts. |

| Infrastructure | Bridge components, railings, utility pole hardware, tunnel and substation fittings. |

| Custom Fabrication | Any situation where standard bolts are too short or need modification. |

Technical Specifications Grade 8.8

| Standard | DIN 975 (replaced in scope by DIN 976-1 in some references) |

| Material | Medium carbon steel, quenched and tempered |

| Strength Grade | 8.8 (Tensile strength ~800 MPa, yield strength ~640 MPa) |

| Thread | ISO metric coarse thread (e.g., M6, M8, M10, M12, etc.) |

| Length | Typically 1,000 mm or 2,000 mm, with custom cut lengths available |

| Finish | Plain, zinc plated, hot-dip galvanized, or black oxide depending on application |

DIN 975 Grade 10.9 Overview

Grade 10.9 is a high-strength alloy steel class used where very high preload and load-bearing capacity are required.

- Material: High-strength alloy steel, quenched and tempered

- Tensile strength: approx. 1,040 MPa

- Yield strength: approx. 940 MPa

- Significantly stronger than Grade 8.8

DIN 975 Grade 10.9 threaded rods are chosen for critical structural or dynamic-load applications where high clamping force and reliable preload retention are essential.

Purpose of DIN 975 Grade 10.9 Threaded Rods

Grade 10.9 threaded rods are used to:

- Act as a strong and adjustable fastener in assemblies with high preload requirements

- Replace standard bolts where custom lengths or long engagement lengths are needed

- Perform reliably in dynamic, vibrating, or high-stress environments

Get the Best Threaded Rods for Your Project

Benefits of DIN 975 Threaded Rod Grade 10.9

| Benefit | Description |

|---|---|

| Very High Strength | Offers significantly higher tensile and yield strength than 8.8 or 5.8 grades, ideal for critical joints. |

| Fully Threaded | Allows nuts and washers to be placed anywhere along the length, giving maximum flexibility in installation. |

| Cut to Length | Can be cut to any required length in the workshop or on site for project-specific details. |

| Versatile Use | Compatible with ISO metric nuts and washers (e.g., DIN 934, DIN 125 and related hardware). |

| Safe for Critical Loads | Suitable for dynamic, vibrating, or seismic applications due to high clamping force and preload retention. |

| Coating Options | Available in plain, zinc plated, hot-dip galvanized, or black oxide finishes for different environments. |

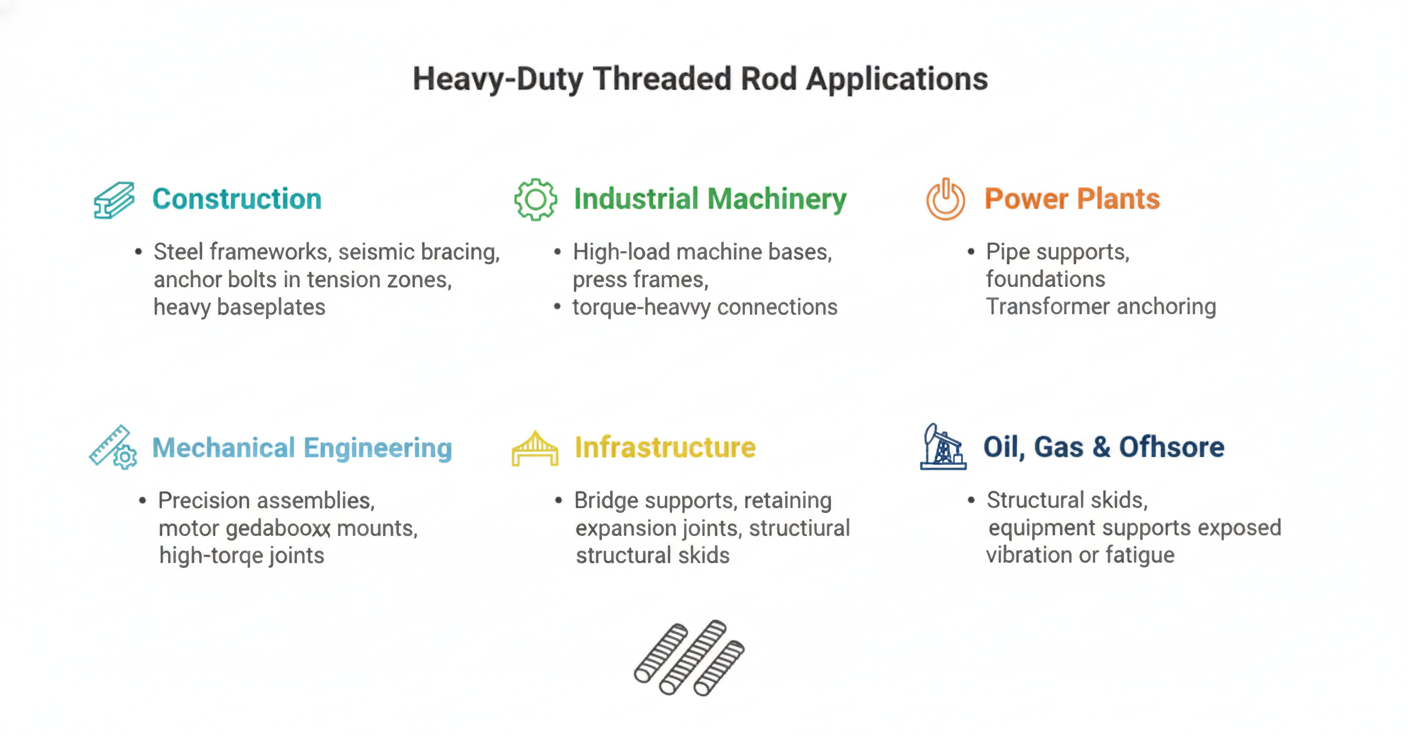

Applications DIN 975 Grade 10.9

Grade 10.9 threaded rods (DIN 975) are used where very high strength and reliable preload are required.

| Sector | Examples |

|---|---|

| Construction | Steel frameworks, seismic bracing, anchor bolts in tension zones, heavy baseplates. |

| Industrial Machinery | High-load machine bases, press frames, torque-heavy connections. |

| Power Plants | Pipe supports, turbine foundations, transformer anchoring. |

| Mechanical Engineering | Precision assemblies, motor and gearbox mounts, high-torque joints. |

| Infrastructure | Bridge supports, retaining systems, expansion joints, structural skids. |

| Oil, Gas & Offshore | Structural skids, equipment supports exposed to vibration or fatigue. |

Technical Specifications Grade 10.9

| Standard | DIN 975 (referenced alongside DIN 976-1 in some standards) |

| Material | High-strength alloy steel, quenched and tempered |

| Strength Class | 10.9 (tensile strength ~1,040 MPa, yield strength ~940 MPa) |

| Thread | ISO metric coarse thread, fully threaded |

| Lengths | Typically 1,000 mm or 2,000 mm, with custom lengths available |

| Finish Options | Plain, zinc plated, hot-dip galvanized, black oxide depending on environment |

| Reusability | In critical load applications, not typically reused if stressed beyond yield or visibly deformed. |

Grade 8.8 vs 10.9 Which DIN 975 Threaded Rod Should You Choose?

Both grades follow the DIN 975 dimensional standard but offer different strength levels. The choice depends mainly on load, safety factors, environment, and cost.

| Parameter | Grade 8.8 | Grade 10.9 |

|---|---|---|

| Strength Level | High strength for most structural and mechanical needs. | Very high strength for critical and high-preload joints. |

| Typical Use | General construction, MEP, machinery, plant supports. | Seismic bracing, heavy machinery, power plants, high-stress industrial applications. |

| Cost | More economical; often sufficient for most BOQ items. | Higher cost; used where design specifically demands 10.9. |

| Dynamic Loads | Suitable for moderate dynamic loads when correctly sized. | Preferred for vibration, fatigue, and high dynamic loading. |

| Specification Approach | Use when standard high-strength threaded rod is specified. | Use when consultant or code clearly requires 10.9 or higher property class. |

For value, many projects specify Grade 8.8 as the default. Grade 10.9 is reserved for locations where structural calculations, vibration, or safety factors justify the extra strength and cost.

Why Engineers Choose Husaini Brothers for DIN 975

As a long-established fastener manufacturer and supplier for the GCC region, Husaini Brothers supports projects from Dubai and Abu Dhabi to Riyadh, NEOM, and Jubail with:

- Stocked and project-based supply of DIN 975 threaded rods in Grade 8.8 and 10.9

- Cut-to-length services for special anchor and assembly requirements

- Material and coating recommendations based on environment and design life

- Support in mapping consultant specifications and BOQs to practical, deliverable items

Whether you are standardising MEP supports, finalising steel connection details, or preparing a shutdown materials list, our team can help you choose the right DIN 975 threaded rod configuration.

Read More: ASTM A193 Grade B7 Threaded Rod Specification Guide | The Ultimate Guide to Fastener Materials and Grades