Fully Threaded Rod & Stud Fasteners for Saudi Arabia Projects

High-strength threaded rods and stud fasteners are at the heart of reliable structures across Saudi Arabia from high-rise towers in Riyadh to industrial plants in Jubail and mega projects across NEOM and the Red Sea.

Husaini Brothers is among the experienced threaded rod suppliers in Saudi Arabia supporting infrastructure, industrial, and mega-project requirements.

Husaini Brothers manufactures and supplies threaded rods and studs engineered for Gulf conditions, with the right length, thread, material, and coating for demanding Saudi applications.

From design to delivery, we make sure your rod and stud specifications are correct, clear, and on time.

Why Saudi Engineers Choose Husaini Brothers

- 57+ years in fasteners for steel construction, industrial, and infrastructure projects

- Specialized in high-strength structural bolting and threaded systems for GCC projects

- DIN / ISO aligned threaded rods and studs, with mill certificates where required

- Custom cut-to-length service for non-standard sizes and site constraints

- GCC-focused logistics for deliveries into Saudi Arabia project sites

Whether you are a steel fabricator, EPC contractor, MEP contractor, or oil & gas supplier, our team helps you match exact thread, length, grade, and coating to your application.

Engineers in Saudi trust Husaini Brothers for mechanical fasteners where every dia is precise and every piece is checked for uncompromising quality.

Product Range Threaded Rods & Stud Fasteners

1. Threaded Rods (All-Thread Rods in Saudi Arabia)

Fully threaded metal rods used where adjustability, clamping force, and alignment are critical.

- Thread coverage: Fully threaded along the entire length

- Diameters (metric): From small diameters for MEP supports to heavy sizes for structural and anchor assemblies

- Standard lengths:

- 1 meter

- 2 meters

- 3 meters

- Custom lengths: Cut to size as per drawing or BOQ

- Thread forms: Metric coarse as standard, other options on request

- Applications: Pipe supports, suspended ceilings, HVAC, equipment supports, anchor bolt assemblies

2. Stud Fasteners in Saudi Arabia

Headless fasteners used where bolts cannot pass through or where frequent assembly / disassembly is required.

- Fully threaded studs

- Double-ended studs (threads on both ends with plain shank in the middle)

- Tap-end studs (different thread length each side for tapped holes and nuts)

Stud fasteners are used extensively in flanges, equipment foundations, machinery, and critical joints that need consistent tightening and serviceability.

Choose the Best Manufacturer for Threaded Rods & Stud Fasteners

Length & Thread Options for Saudi Projects

The right thread and length decision affects load capacity, ease of installation, and future maintenance. Husaini Brothers helps you get this right at the enquiry stage.

Length Options

- Standard rod lengths: 1 m, 2 m, 3 m

- Special lengths and cut-to-length rods for:

- Precast connections

- Deep embedments in concrete

- Tight plant rooms and retrofits

For complex projects, we match rod and stud lengths to your steel drawings, anchor layouts, and equipment baseplates.

Thread Types & Coverage

Fully threaded rods

- For maximum adjustability and flexibility along the entire length

- Ideal where exact positioning of nuts and fixtures is needed

Partially threaded studs

- Plain shank in the middle where shear and bearing are critical

- Common in machinery and flanges

Thread pitch options

- Metric coarse threads as standard

- Fine thread or special thread forms on request

All threads are produced to recognized standards (DIN / ISO / equivalent), ensuring compatibility with nuts, washers, and couplers.

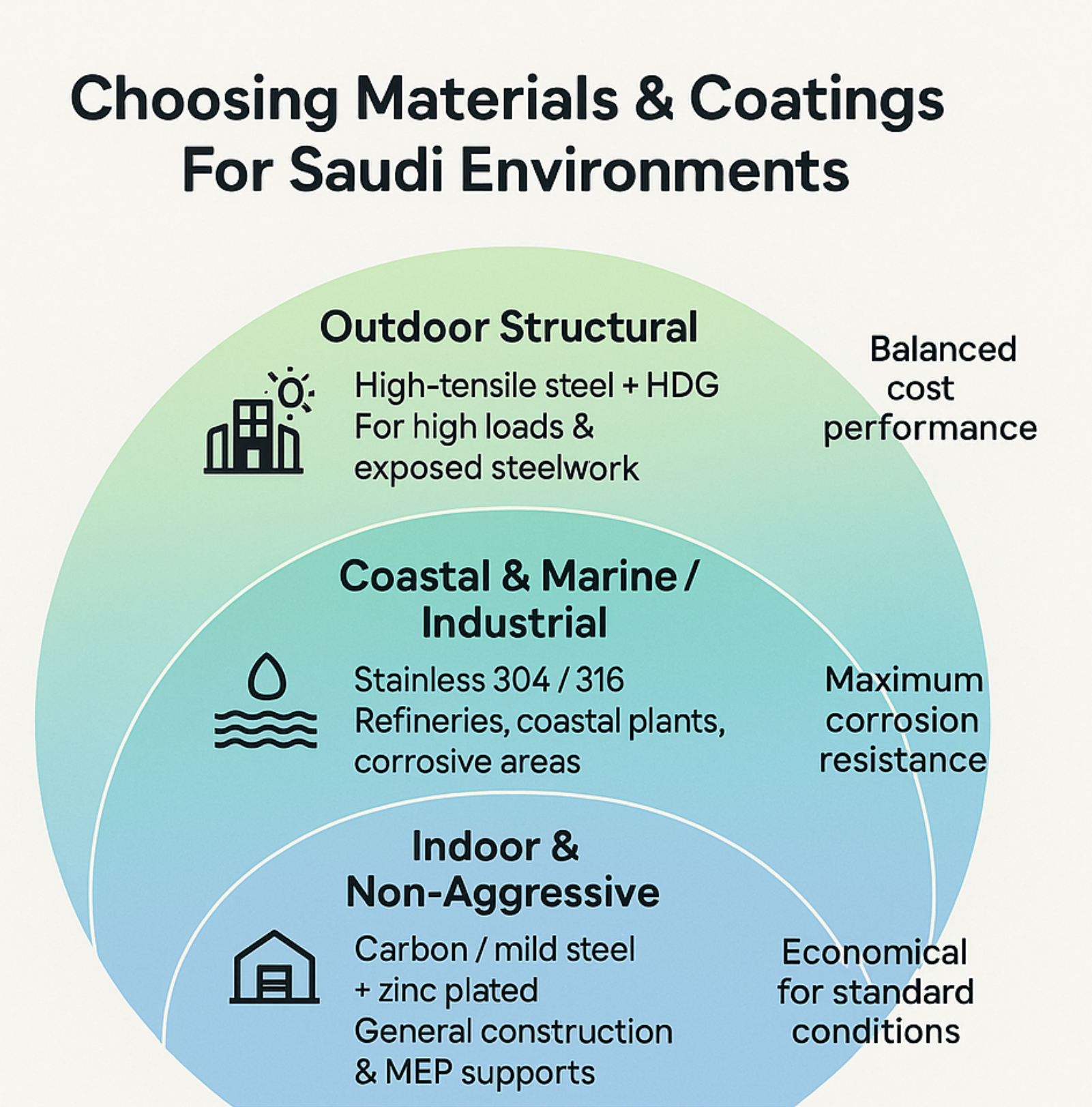

Materials & Coatings

Saudi Arabia's environment demands strength plus corrosion resistance. We manufacturer and supply threaded rods and studs in materials suited to deserts, coastal regions, and industrial atmospheres.

Core Materials

- Carbon steel / mild steel threaded rods: For general construction and non-aggressive environments

- High tensile steel threaded rods: For high load, structural, and anchor applications

- Stainless steel (304 / 316 grades): For coastal, chemical, food, and high-corrosion environments

Coatings & Finishes

- Zinc plated: Added protection for indoor and mildly corrosive environments

- Hot-dip galvanized (HDG): Heavy-duty protection suitable for outdoor and structural use

- Other finishes: Available based on project specification

Our team helps you balance material grade, coating type, and cost to match Saudi project life and exposure conditions.

Build Better Products with Husaini Brothers.

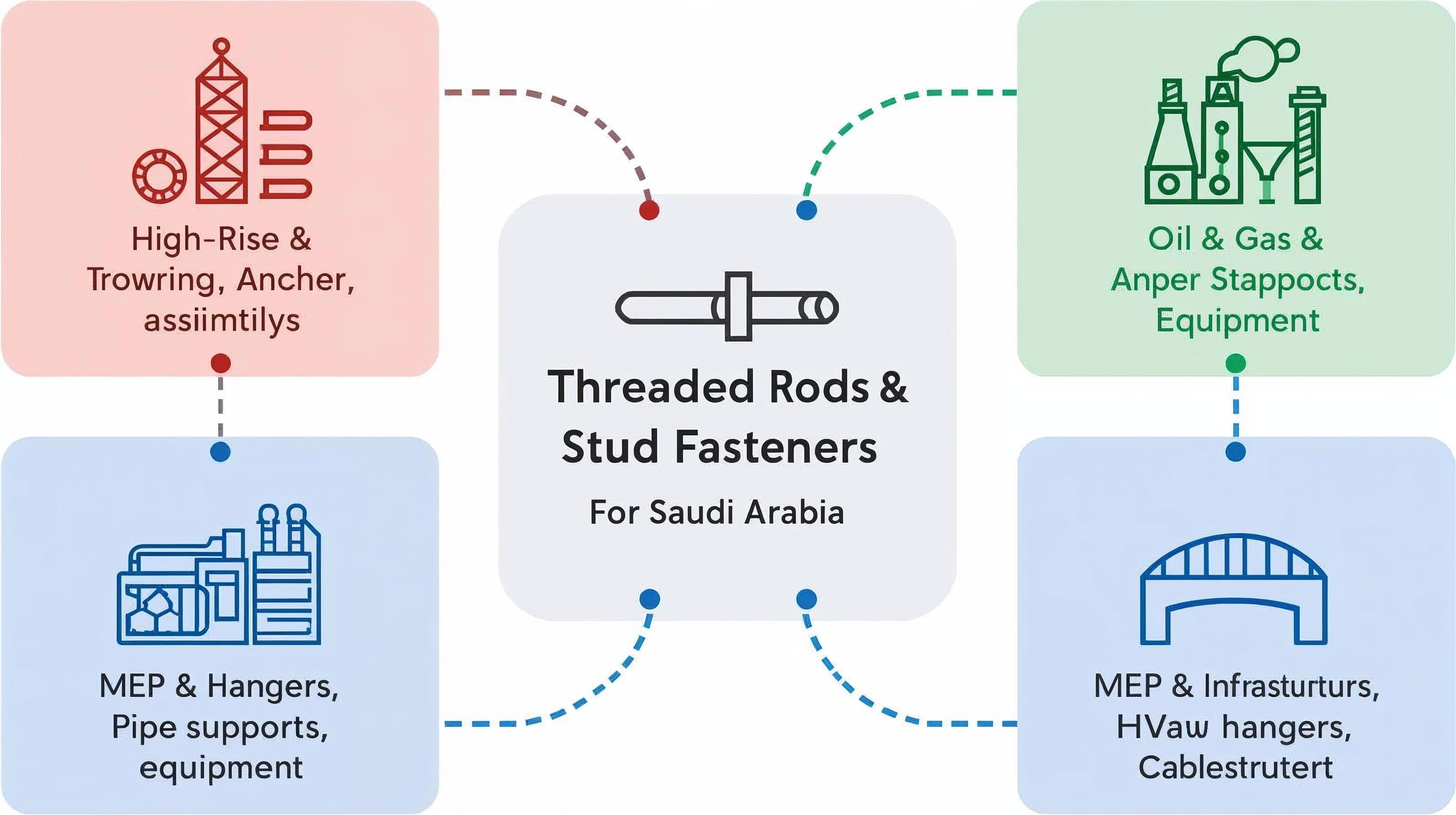

Typical Saudi Arabia Applications

Husaini Brothers threaded rods and studs are used across:

- Steel construction & high-rise buildings

- Structural connections, bracing, and anchor bolt assemblies

- Oil & gas, petrochemical, and refinery projects

- Stud bolts for flanges, pipe supports, equipment foundations

- Power plants & industrial facilities

- Machinery mounting, cable tray supports, pipe hanger systems

- Infrastructure & utilities: bridges, tunnels, substations, water treatment plants

- HVAC & MEP installation: ducting, cable trays, hanging systems, ceiling supports

If your drawing or BOQ specifies threaded rod, stud, stud bolt, or all-thread, we help you match that to a Husaini Brothers product with clear specs.

Technical Snapshot for Saudi Arabia Projects

You can adapt this table for your project documents or BOQ layout.

Parameter |

Options / Details |

|---|---|

| Diameter | Metric range suitable for light to heavy duty |

| Lengths | 1 m, 2 m, 3 m, custom cut lengths |

| Thread coverage | Fully threaded or partial (for studs) |

| Thread form | Metric coarse as standard |

| Materials | Carbon steel, high tensile steel, stainless |

| Coatings | Black, zinc plated, hot-dip galvanized |

| Standards | DIN / ASTM / equivalent on request |

For stud fasteners, we align with your plant specifications, equipment manuals, and consultant requirements.

What We Need From You for a Fast Quote

To quote accurately for your Saudi Arabia project, share:

- Threaded rod or stud type:

- Rod / fully threaded stud / double-ended stud / tap-end stud

- Diameter and length

- Quantity per size

- Material grade and coating

- Applicable standard, if specified (DIN / ISO / ASTM, etc.)

- Delivery location in Saudi Arabia

- Any testing or certification requirements

You can attach your BOQ, drawings, or consultant specs and our team will map them to a complete threaded rod and stud package.

Talk to Husaini Brothers About Your Saudi Project

Whether you are:

- Finalizing anchor details for a new plant

- Standardizing MEP support systems

- Procuring stud bolts for shutdowns or turnarounds

- Or setting up long-term fastener supply for multi-year projects

When choosing a threaded bar or threaded rod in bar stock for construction or MEP work, engineers often go for stainless steel threaded options, especially 304 stainless steel, when corrosion resistance, high strength, and long-term durability are critical.

A relatively long rod that is threaded must be specified correctly: the length of the rod, thread size, and strength class must suit the load, whether it functions like a screw, a suspension member, or part of a connector assembly with nuts and washers providing full engagement along the full length of the rod.

A rod in bar stock form is typically round, and this bar stock form is often supplied as a steel fully threaded solution for maximum flexibility; this stock form is often called a threaded bar, or all-thread, in site language.

You can buy threaded rods in a variety of sizes, such as 12 mm, and in different materials including brass, copper, aluminium, and carbon steel, with hex nuts and accessories to create secure fastening systems.

In many industrial and structural applications, bar stock supplied in bar stock form is often cut into custom lengths, used as a long rod, and integrated with couplers and anchors so that the system remains adaptable, spec-correct, and reliable over the life of the project.

Read More: ASTM A193 Grade B7 Threaded Rod Specification Guide | DIN 975 Threaded Rods Grade 8.8 & 10.9 Specification Guide